A complete listing of temper designations and descriptions for copper and copper alloys cane found in astm b601 standard practice for temper designations for copper and copper alloys wrought and cast.

Copper sheet rolling temperature.

The recrystallization temperature is that temperature at which the crystal lattice structure of the metal.

The process was subjected to a gradient of elevated temperatures reaching 200 c.

1 the anisotropy of young s modulus of copper sheet subjected to forward cold rolling to a reduction of 70 is determined primarily by the fourth harmonic of the expansion of the modulus curve.

The copper forming process.

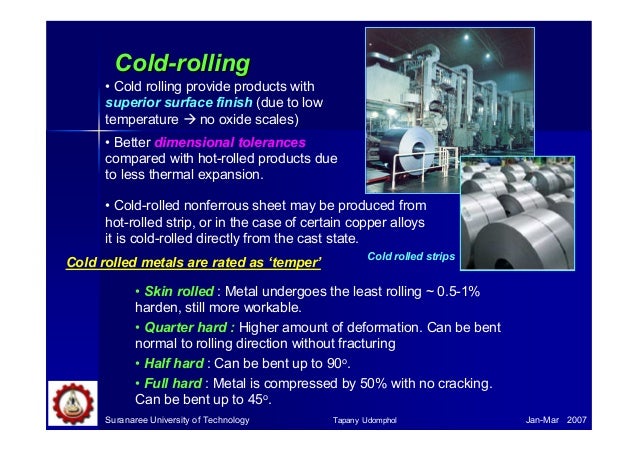

In metalworking rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform.

Copper processing copper processing roasting smelting and converting.

If the temperature of the metal is above its recrystallization temperature then the process is.

Hot rolling is carried out at temperatures above the recrystallization temperature of the metal.

Additional information on physical properties and cold rolled tempers is available in data sheets from material suppliers asm metals handbook volume 2.

Once a concentrate has been produced containing copper and other metals of value such as gold and silver the next step is to remove impurity elements.

The copper forming process.

The concept is similar to the rolling of dough rolling is classified according to the temperature of the metal rolled.

The recrystallization temperature is that temperature at which the crystal lattice structure of the metal.

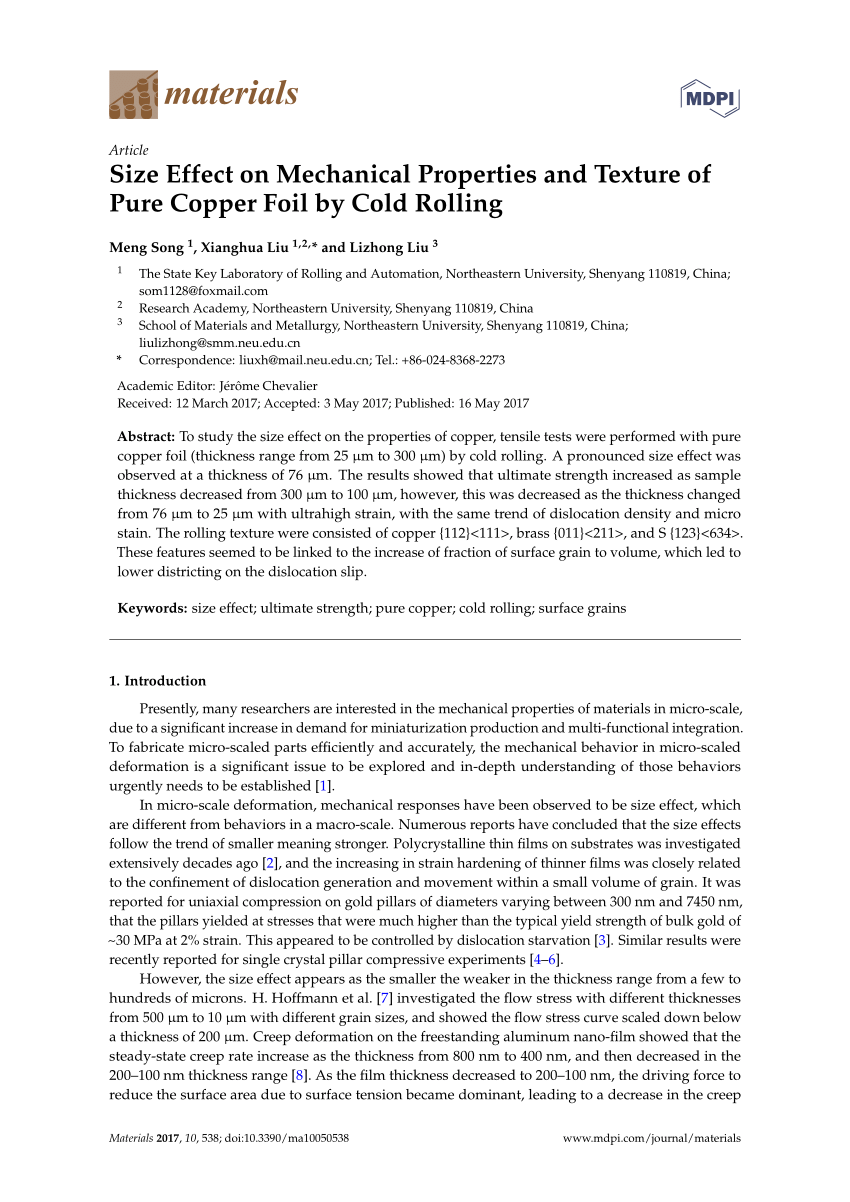

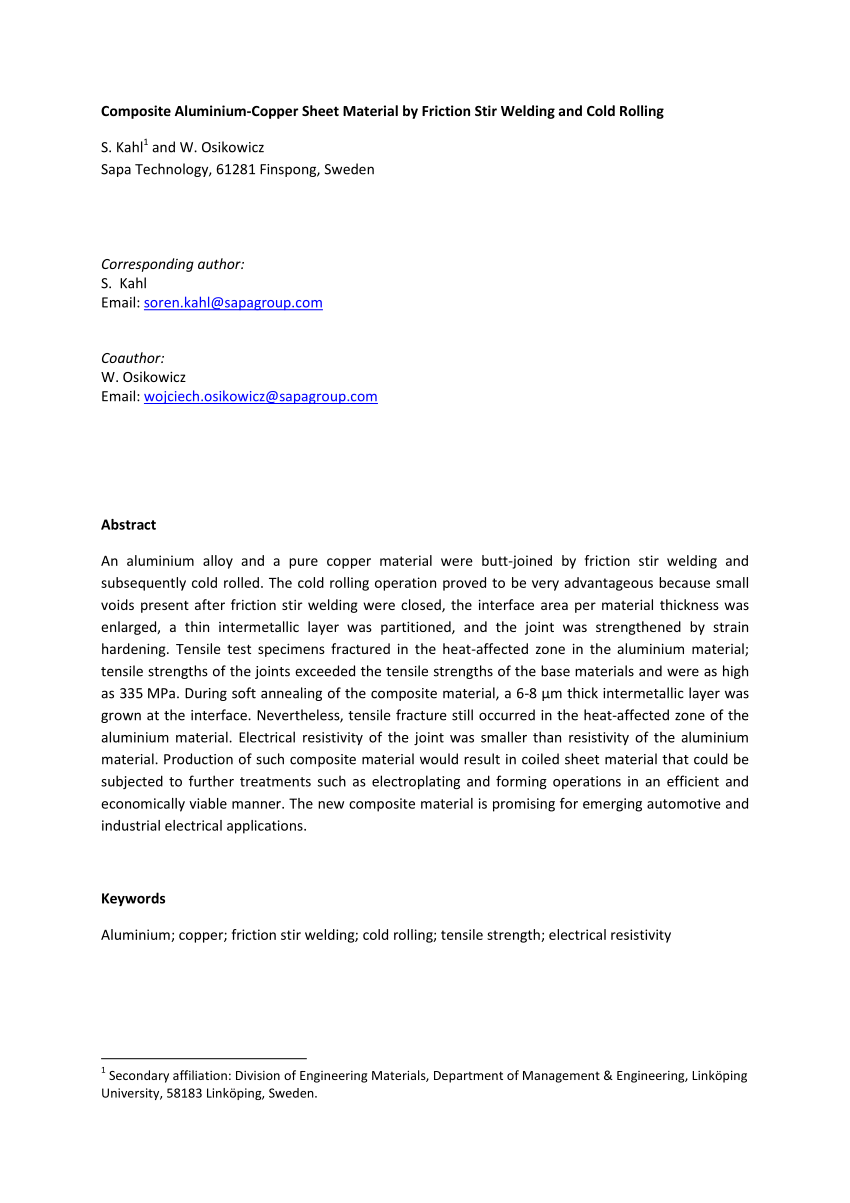

The microstructural evolution and mechanical properties of cu sheets were investigated by metallographic characterizations tensile tests and fracture analysis.

The total thickness was reduced by 55 through three rolling passes.

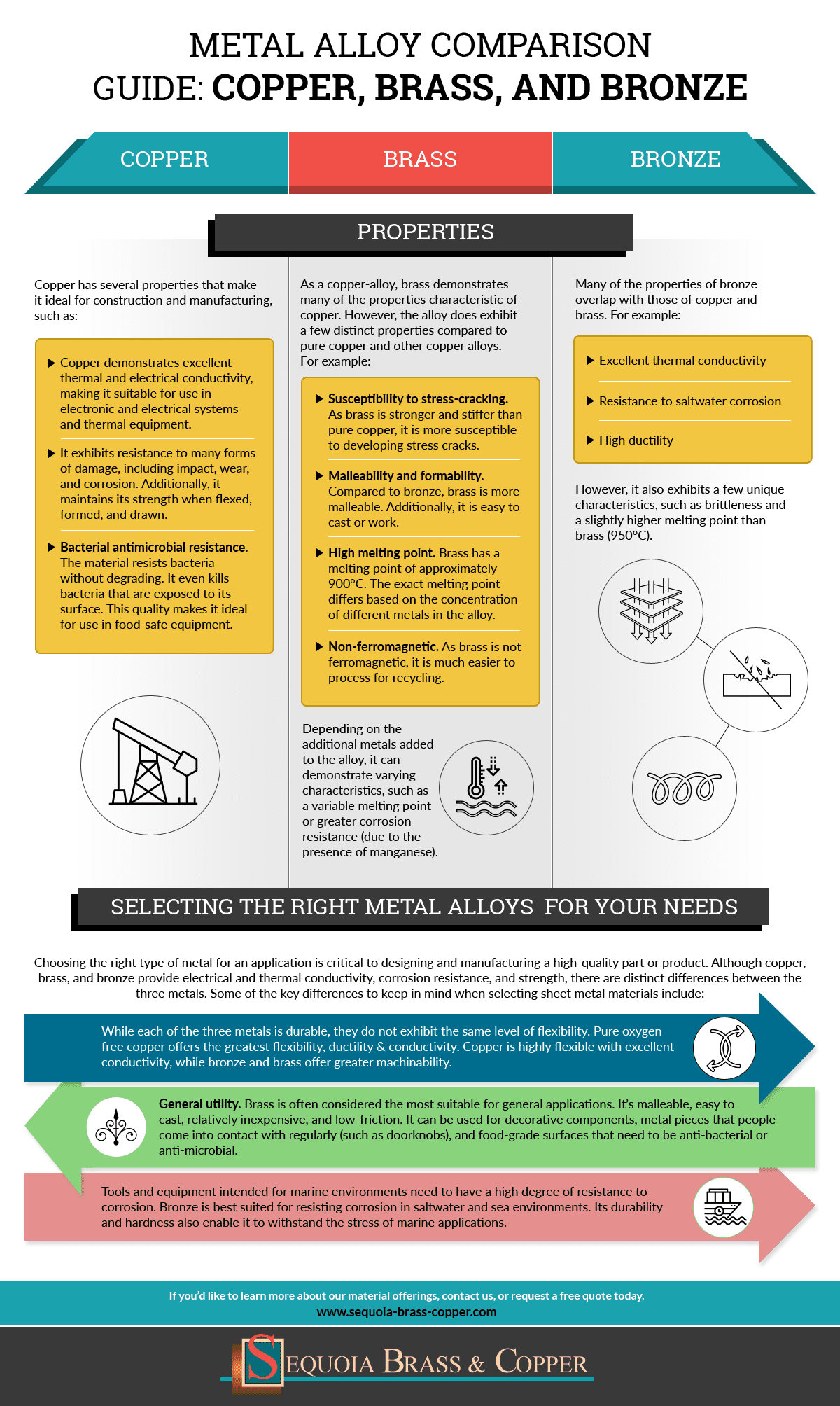

Copper is the only solid surface material registered by the u s.

Environmental protection agency to continuously kill bacteria that pose a threat to human health.

In older processes the concentrate containing between 5 and 10 percent water is first roasted in a cylindrical refractory lined furnace of either the hearth or.

No other touch surface material has this kind of registration.

The effect of temperature on hardness and microstructure in rotary bending of copper sheets was investigated.

Nonetheless there are several subtleties and exceptions.

Five different processes plus variations within those five processes are used to form copper.

Five different processes plus variations within those five processes are used to form copper.

Hot rolling is carried out at temperatures above the recrystallization temperature of the metal.

For the r foil the as cast grain structure as well as the cellular dislocation substructure becomes stretched during rolling.